email [email protected] phone +33 (0)1 43 99 00 22

Solar protection 68%, Silver

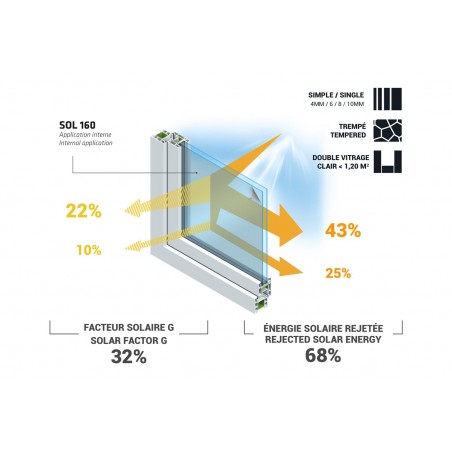

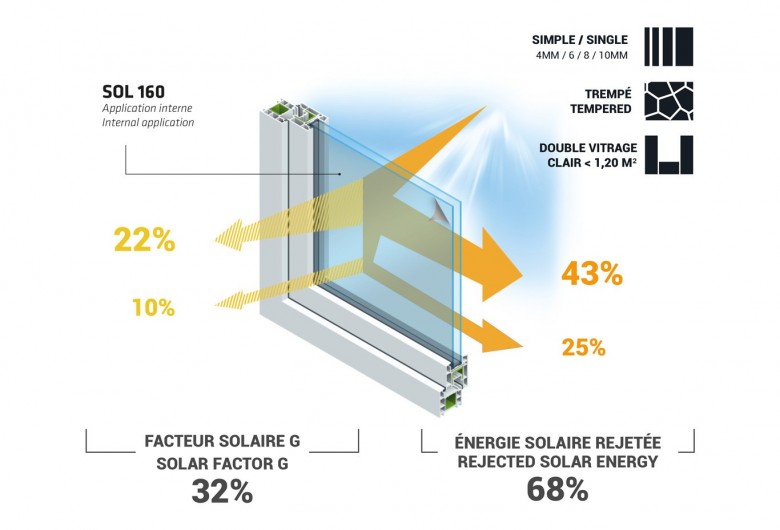

The SOL160 solar protection film has a TSER* of 68% and is usable for internal application only.

This adhesive film has been developed to be applied on glazing, aiming to reduce heat transmission and sun glare.

It spectacularly improves comfort inside buildings exposed to the sun, and is a real improvement factor for comfort, and energy savings (related to climatization).

*TSER : Total Solar Energy Rejected

Solar protection films composition

The solar protection films are made of two metalized PET layers, an adhesive coat, and an additional protective layer which has to be removed before the application. They also all have an anti-scratch treatment.

Solar Factor (G)

The Solar Factor (G) of any glazing is the ratio between the total energy entering the room through the glazing and the incident solar energy. The total energy is the addition of the incoming solar energy by direct transmission, and energy released by the glass in the indoor environment, which has been heated by energy absorption

Greenhouse effect

Solar energy entering a room through glazing is absorbed by the objects and interior walls which, as they heat up, re-emit thermal radiation mainly in the far infrared range (above 5 μm). Glazing, even clear glazing, is practically opaque to radiation of wavelengths greater than 5μm. The solar energy entering through the glazing is therefore trapped in the room, which tends to heat up: this is the "greenhouse effect" that can be seen, for example, in a car parked in the sun with the windows closed.

| Material | PET |

| Color | Silver |

| Adhesive | Polymer acrylic 19g/m² |

| Liner | Siliconed PET 23 microns |

| Thickness | 70 microns |

| Application Face | Interior |

| Guarantee | 10 years* |

| UVA transmission | 1% |

| Facteur Solaire G | 32% |

| Energie Solaire Rejetée | 68% |

The glass surface to be glued on has to be free from dust, grease or other contaminants. Some specific materials such as polycarbonate can cause air bubble problems. Therefore, a compatibility rest is recommended. Please refer to our prescription table or contact us for any question

Before applying to our users to ensure that the film is suitable for the intended use and comply with current standards. In order to constantly improve our production we may change a product colour and manufacturing process without prior notice.